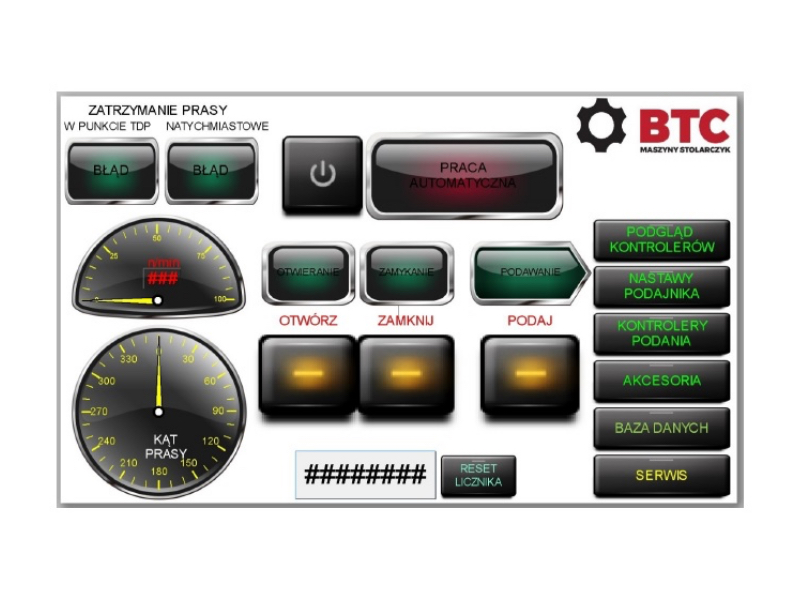

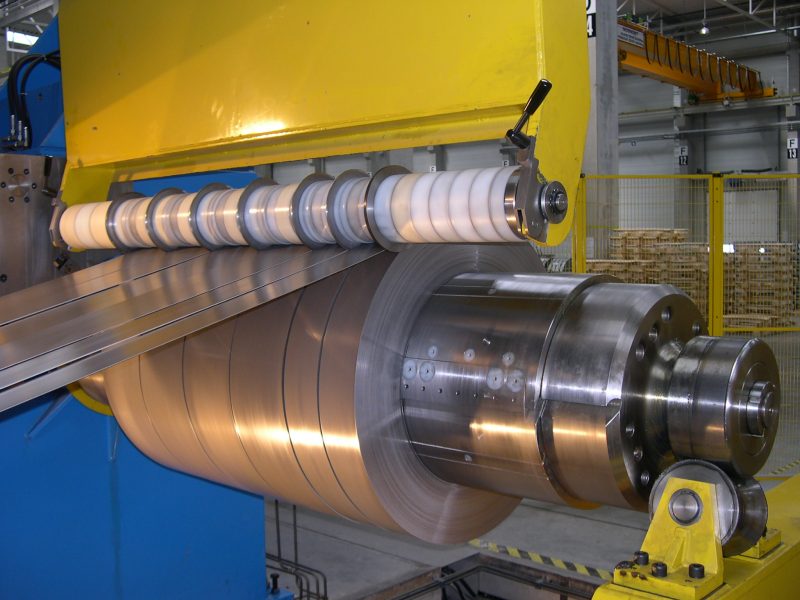

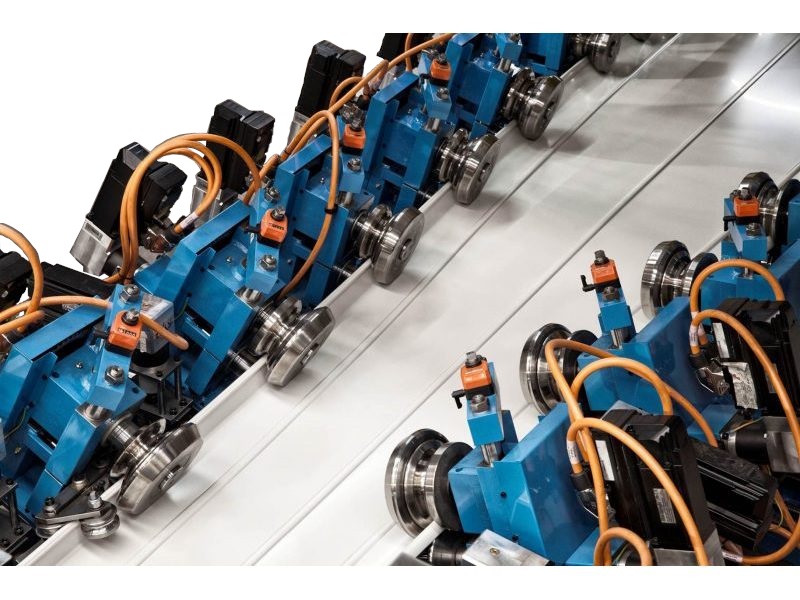

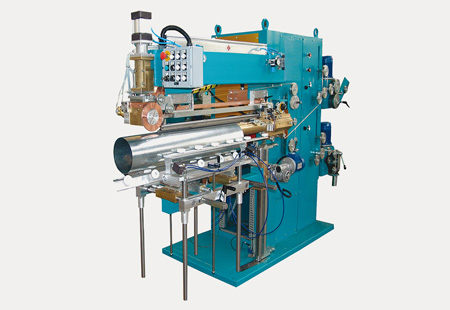

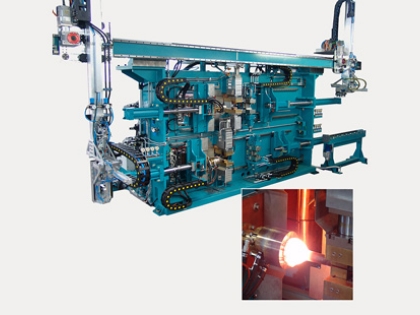

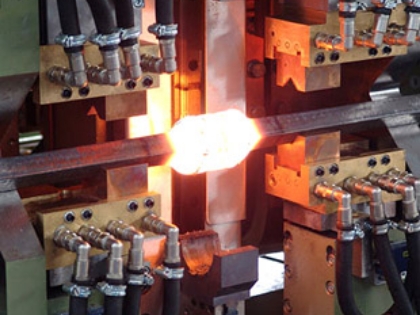

The plate bending process is an operation that deforms material by giving it a preset curvature using rolling rollers. It is carried out thanks to a plate bending machine. A sheet of metal during rolling, is inserted between the rollers, where, as a result of their appropriate positioning, pressure and rotation, it is displaced and curved. Bending parameters are obtained by changing the position of the rollers. Control can be done manually from the operator’s panel or by means of numerical control. Coiling machines produce cylindrical, conical or polycentric tubes of different thicknesses. To achieve a good end result, it is therefore extremely important to choose the right machine.